Product Description

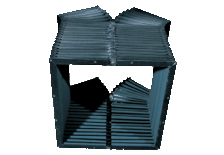

Bellows

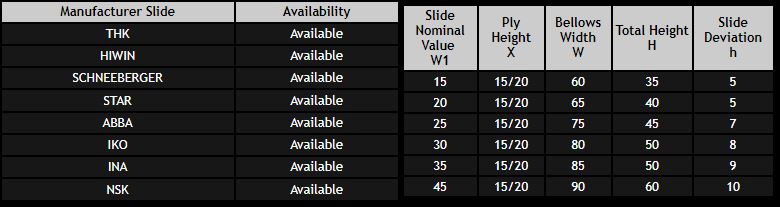

SIGNAGE offers bellows for machine locations that will not have heavy chip exposure, but still need to protect the sensitive components of the machine. Bellows offer protection from contaminates while applying little resistance to the machine's movement. Metal plates can be attached to the bellows if exposed to a light chip environment.

With bellows you have the following Advantages: Guide Protection, Accident Prevention, High Translation Speed, Minimum Necessary Dimensions, Easy Assembly, Wide Choice of Materials, Long Life, WaterTight, Protects from Dust and Debris.

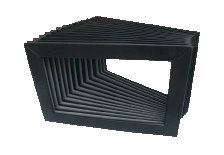

Conventional Bellows - Glued and Finned Bellows

These are authentic general purpose bellows manufactured with internal PVC support glued with an extenal PVC coating, resistant to dust, coolants spray, temperatures ranging from 30C to 75C. It also comes with lamellas, scissor frames etc to meet the complicated requirements of the machines.

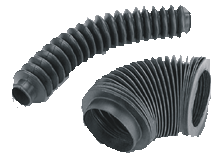

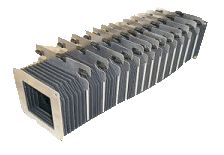

Sewn & Thermo Weld Bellows

Sewn bellows are used when strong movement is required. And where a compact closed pack is required. It is a excellent protection for shafts, worm screws, ball recirculation screws, made of rings of various materials and thicknesses for all applications.

They are stress- resistant covers. Every fold is supported by a PVC frame, fixing between Frames and shell is by welding(thermo- weld using high frequency, without glues) In this way we have heat sealed elements which resist stress and are watertight.

Using The Resources of Highly Qualified Technology - High Frequency Thermo Welding, At SIGNAGE, we prepare and test products of Different compositions with the objective of maximum realibility : Folding covers made to measure, adaptable to all types of machines.

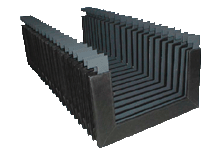

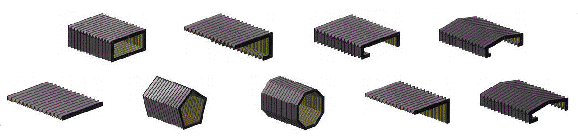

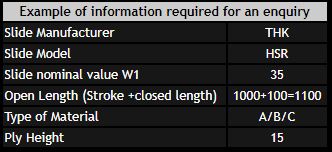

LM Guide Thermic Welded Covers

- Address :

- #452, 12th Cross, 4th Phase,Peenya Industrial Area,Bengaluru - 560058